Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

Type: Modular Polyurethane screen panels, dewatering Polyurethane screens, Polyurethane trommel screens, Polyurethane, and wedge wire screen

Application Equipment: dewatering screen, vibrating screen

Application Industries: coal washing plants, coking plants, mines, power plants, dredging companies, metallurgy, petroleum, petrochemical, and other enterprises.

Product Details

Polyurethane screen panels are a kind of screening filter media made of polyurethane raw material. Which are also called polyurethane sieve plates, polyurethane screens, polyurethane screed, polyurethane screen media, etc.

The latest production technology is adopted to make polyurethane screen panels have novel structures, convenient installation, and disassembly. Our polyurethane screen panels are widely used in coal washing plants, coking plants, mines, power plants, dredging companies, metallurgy, petroleum, petrochemical, and other enterprises. Polyurethane screen is the replacement product of steel punching mesh, steel woven wire mesh, stainless steel sieve plates, and rubber sieve plates.

Polyurethane screen panels are a very good alternative to steel woven wire screens. The main advantages are exceptional abrasion resistance, lack of corrosion, low noise levels, and exceptional precision during operation. They provide a perfect constant screening performance, do not mix fractures, and do not crack under vibration. In addition, PU panels are repairable.

Polyurethane screens offer a lifespan that is up to 10 times longer compared to woven wire screens. Therefore, they reduce operational and labor costs. On the other hand, their flexible structure allows the screen to flex and helps to reduce clogging and blinding. Lower weight also contributes to lower energy consumption in the long run.

We manufacture and supply polyurethane screens in different sizes, shapes, patterns, and apertures.

Our polyurethane screens type: Modular Polyurethane screens, dewatering Polyurethane screens, Polyurethane trommel screens, Polyurethane and wedge wire screen

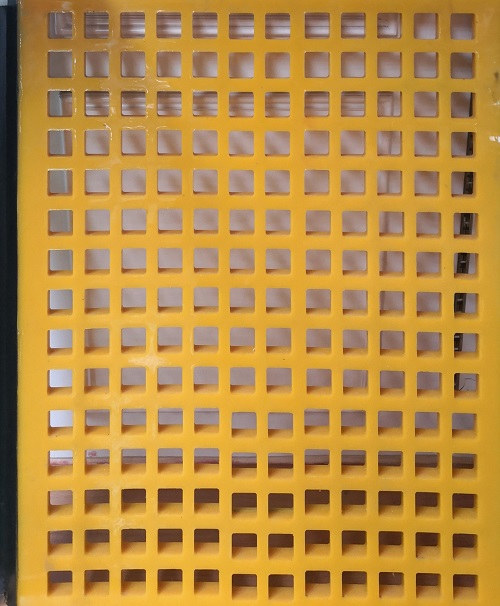

1. Modular polyurethane screens are suitable for a large number of applications. Their special design allows for easy installation with various connection options. Modular screens can be grooved on the sides to slide in or have special locks that fit each other. The panels can also lock onto the rails of the screen box bracing. Fitting modular screens will save you time on installation and replacement. These panels can also be changed individually without affecting others. The panels are repairable.

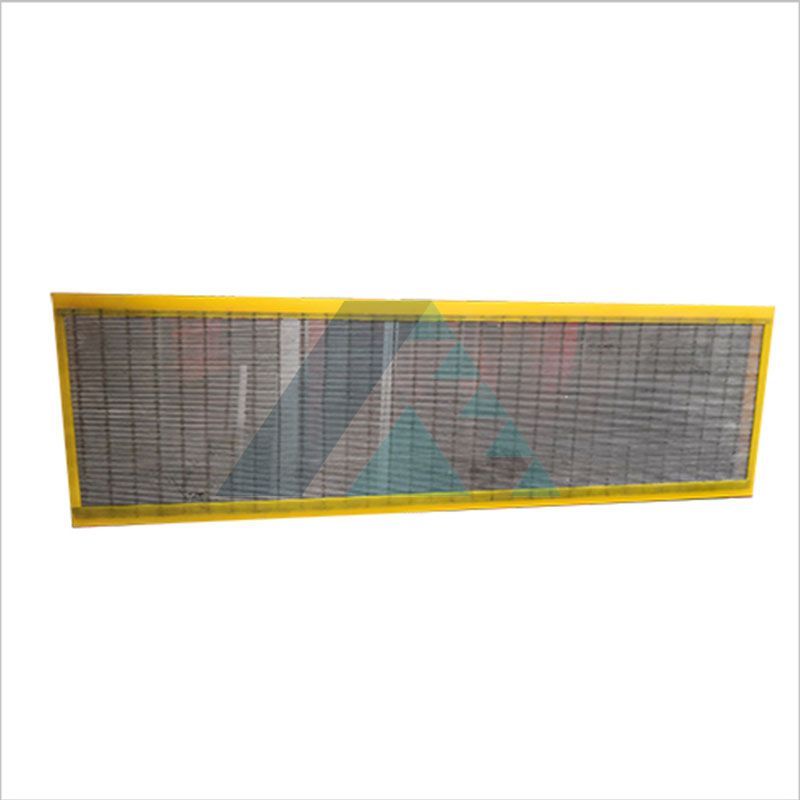

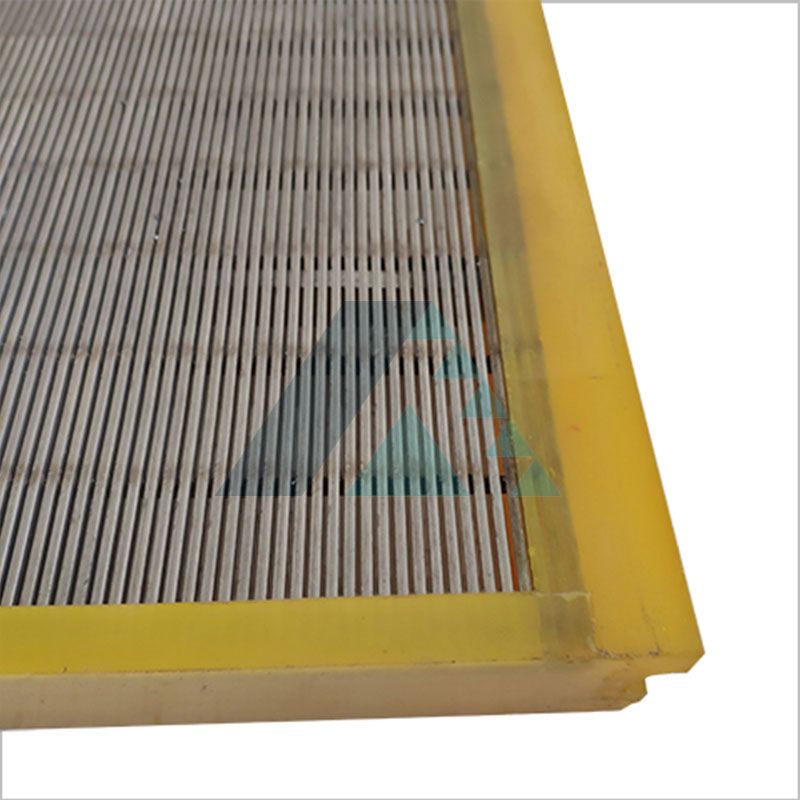

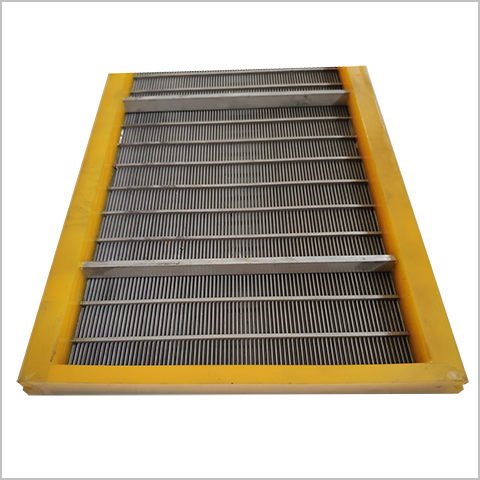

2. Dewatering Polyurethane screens: This type of screen panel performs best in fine screening and dewatering applications. Smaller modules with very small aperture sizes are cast into large frames to form a rigid large panel. These panels join together to form the screens.

3. Polyurethane trommel screens: This type of polyurethane screen is designed for specific applications. Trommel Polyurethane screen media is specially designed to be used in Trommel screens. These screens provide one of the best separation efficiencies despite having a smaller overall screening surface. You can see Trommel screens perform after the mills and scrubbers or in recycling plants.

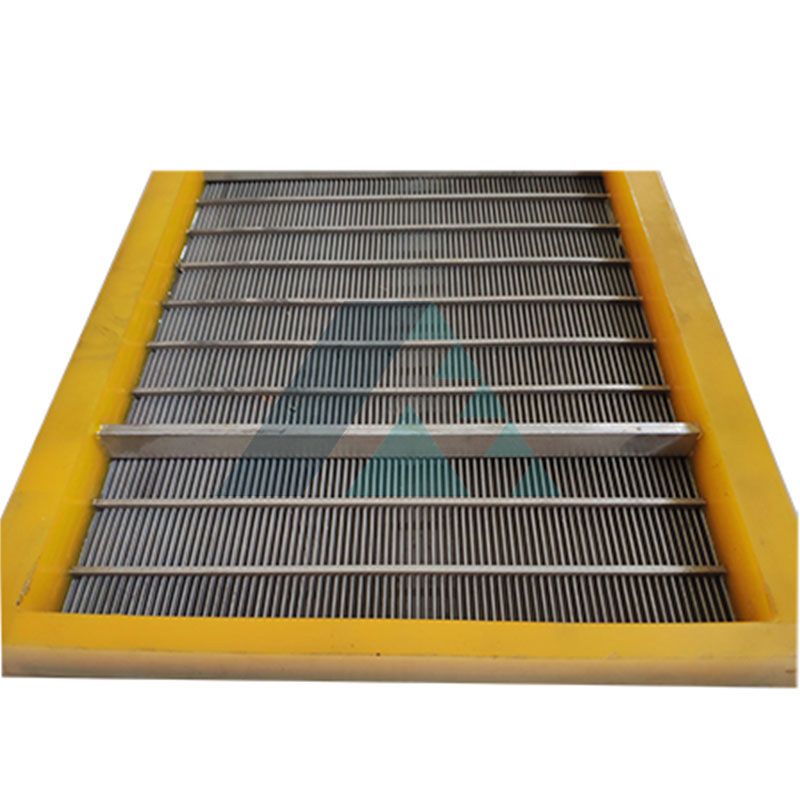

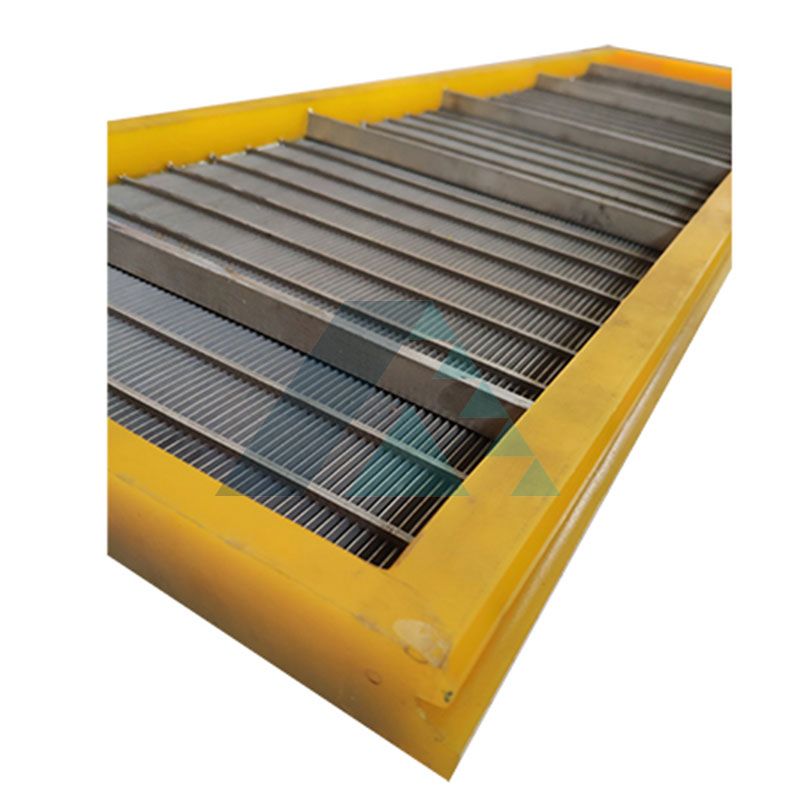

4. Polyurethane and wedge wire screen Filter media: Polyurethane is surrounded by a wedge wire screen plate. This type of polyurethane sieve plate not only has the advantages of a wedge wire screen but also has the advantages of a polyurethane screen. It is the most popular one in the mining and coal mining industry.

What are the main application areas for Polyurethane Screens? | What are the Polyurethane Screens used for? |

Aggregate Processing Washing Applications Cement Manufacturing Asphalt Plants Mining Applications | Screening Sizing Separating Grading Shifting Washing |

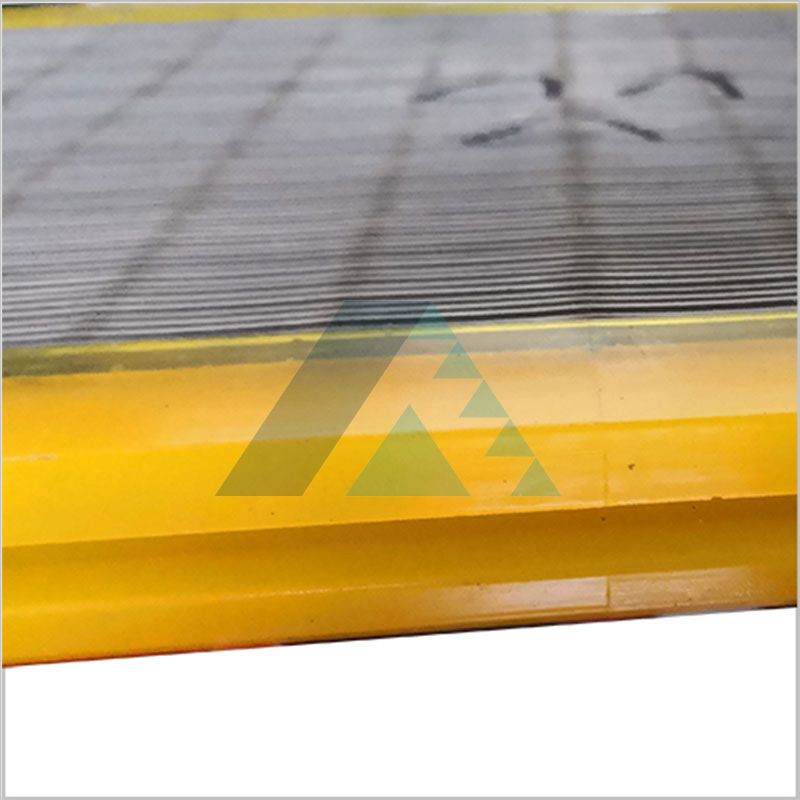

Our polyurethane screens are manufactured with an internal steel frame to your specified size and can be supplied flat or rolled.

The fixing method for your polyurethane screens is determined by your application requirements and can be either bolt-on, hold-down pin, clamp down, or clip-on.

The entire product lifecycle of your polyurethane screens, from design to monitoring of equipment is managed by our in-house to deliver optimum, streamlined performance.