Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

Resin Traps---Cost & Effective Filter Insurance

Water Treatment resin trap is designed and manufactured to meet your specific needs. After you choose a resin trap screen, you can save the cost in terms of resin retention and prevent system downtime.

Product Details

Resin Traps--Cost & Effective Filter Insurance

Resin Traps--Cost & Effective Filter InsuranceA Johnson water treatment resin trap is always there to protect you against losses – gradual resin loss that may escape your notice as well as a catastrophe that sends a large amount of resin down the line unexpectedly.

Water treatment resin trap strainer used in water treatment processes namely in 'Ion Exchange' and other numerous media filter systems, our company offers a Resin Trap Screen. This screen system is primarily used as a safety device and is positioned immediately after the outlet nozzle of the vessel/reactor.

--Loss of expensive resin

--Cross-contamination of resin

--Damage to equipment further down the line

--Costly downtime and process disturbance

-- High mechanical strength can bear large pressure drop

-- Equal slots for filtering can form equally distributed filter cake

-- The wedge-type slot can improve backflushing and regeneration performance

-- It is resistant to pressure-temperature aging corrosion that can be applied to different kinds of fluid.

Water treatment systems can suffer damage through a variety of factors. Many of these systems employ small granular, plastic, powdered, pelletized, and crystalline media within pressure vessels. Despite the development of intricate screens, slotted pipes, perforated plates, and molded devices over time to retain the media, damage can arise from corrosion, chemical corrosion, thermal stress, sudden flow fluctuations, aging of systems, and the impact of water hammer events.

When distribution systems within these setups become compromised, ion exchange resins or other media can enter the water distribution network, resulting in contamination or degradation of downstream components. This includes costly RO membranes, high-value membrane filters, pumps, tanks, piping, various processes, and any products that come in contact with the tainted water.

Resin traps, alternatively known as media traps, are purposefully designed to be retrofitted onto existing or newly constructed strainer bodies. Their role is to capture and prevent the loss of media and resins, averting their migration downstream.

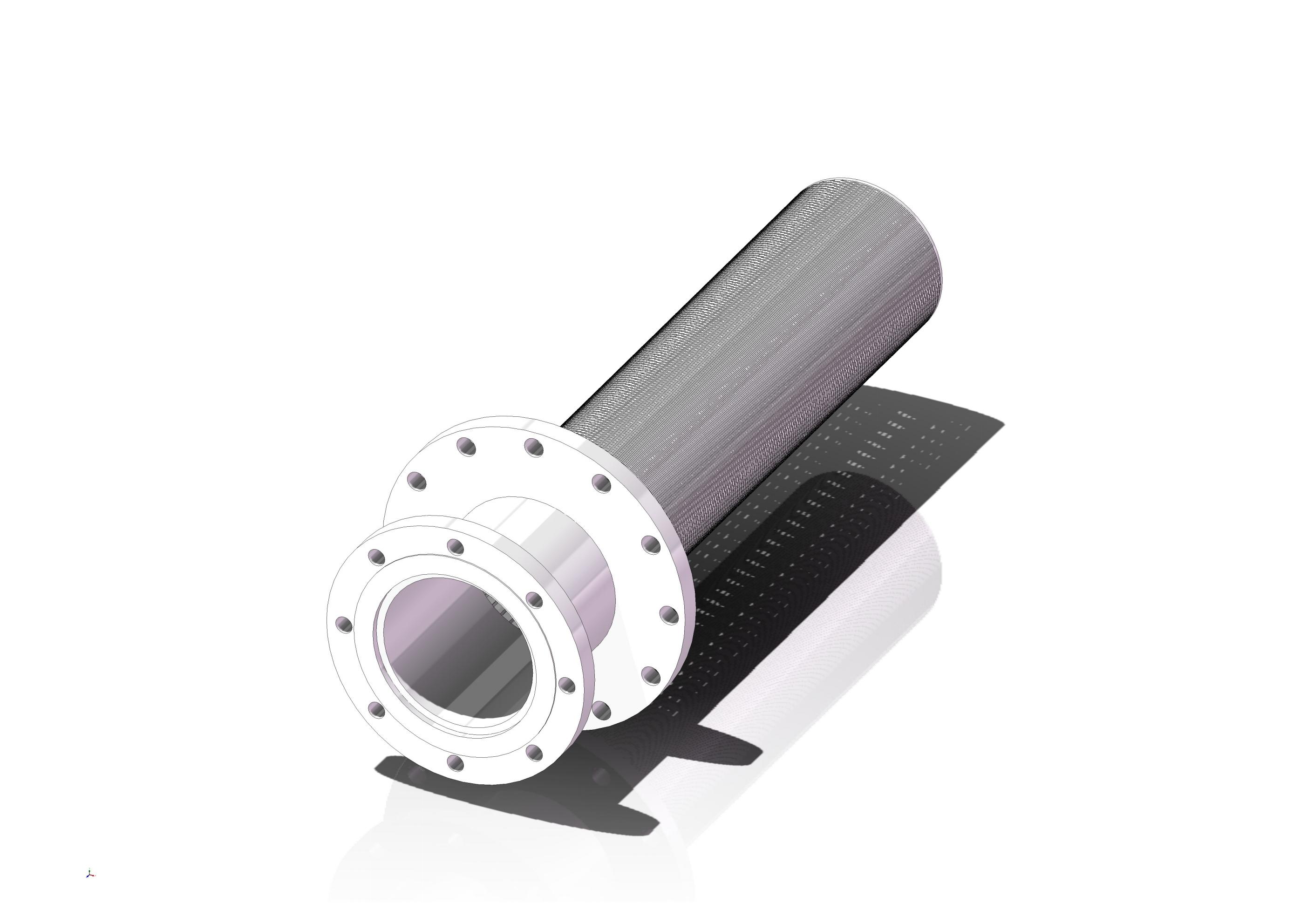

Typically featuring a closed side and a flanged side for straightforward installation onto equipment, resin trap screens intercept and capture passing resin or media. Simultaneously, the accumulated resin can be expelled from the system automatically by flushing, utilizing the differential pressure between the front and rear of the trap.

For effective implementation, resin traps or media traps should be integrated into the product water lines of various resin and media-based water treatment equipment, such as softeners, alkalizes, condensate polishers, demineralizes, carbon filters, sand filters, portable DI tanks, greensand filters, and multi-media filters.

Furthermore, it's prudent to consider the incorporation of a resin trap within the backwash lines of ion exchange and carbon systems. This precaution is crucial due to potential temperature-induced flow variations that could lead to the inadvertent disposal of these valuable materials down the drain.

Embodying precision and adaptability, our wedge wire water treatment resin traps are meticulously designed and manufactured to align seamlessly with your distinct requisites. Our design flexibility has paved the way for a multitude of reliable and economically viable construction possibilities. Whether your preference leans towards stainless steel 304, 316, or the allure of exotic alloy options, the tangible benefits in terms of optimal resin retention and safeguarding against system downtime eclipse the associated costs.

At the heart of our expertise lies custom manufacturing. Our adept sales, engineering, and production teams possess the acumen to actualize your unique specifications with unwavering excellence. By maintaining an in-house approach to every facet of production, we ensure a standard of precision and uniformity that underpins our offerings.

Our seasoned experts adopt a holistic perspective, considering mechanical, operational, and chemical exigencies. This comprehensive approach ensures that you don't merely receive a transitory solution, but rather an enduring fix tailored to perfection.