Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

V Wire Screen, also known as Wedge Wire Screen and Profile Wire Screen, is a versatile screen material supplied in stainless steel and various special steel alloys. It finds its primary applications in dewatering equipment and rainwater harvesting systems.

Product Details

V Wire Screen, also known as Wedge Wire Screen and Profile Wire Screen, is a versatile screen material supplied in stainless steel and various special steel alloys. It finds its primary applications in dewatering equipment and rainwater harvesting systems.

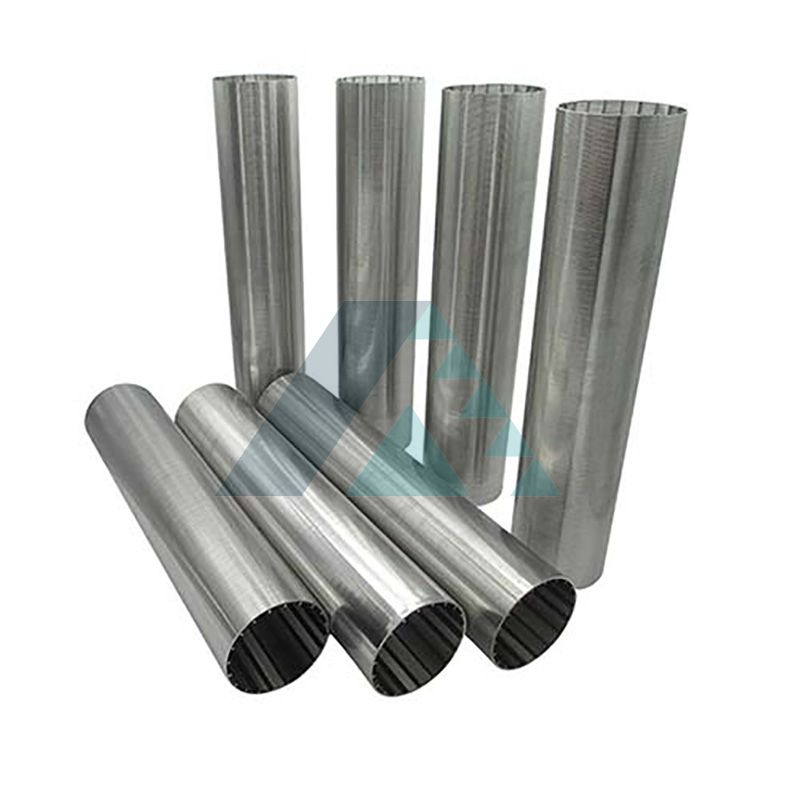

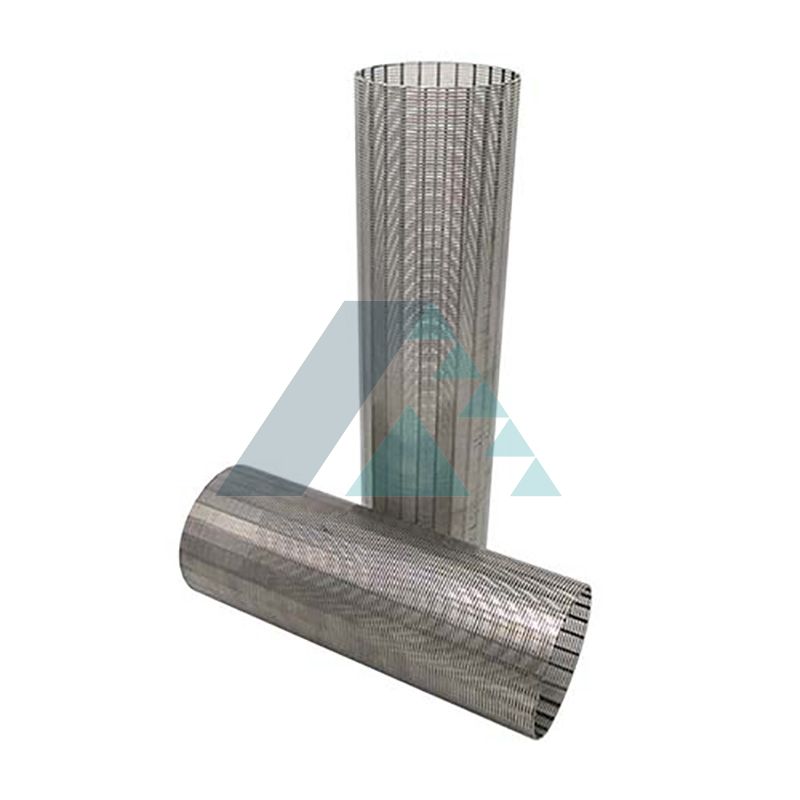

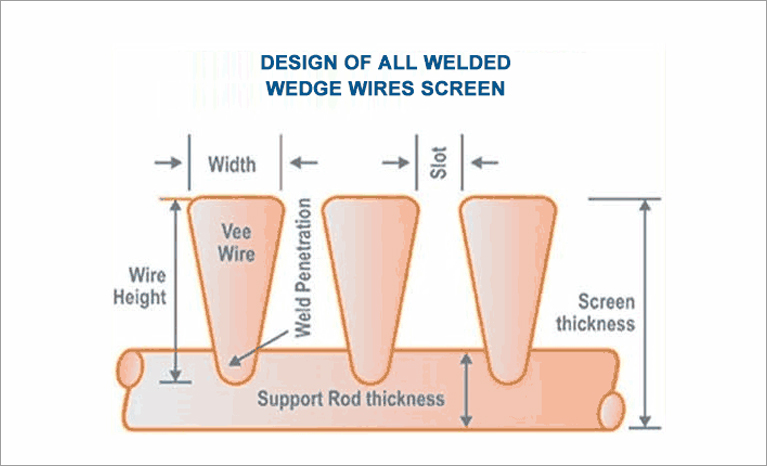

V Wire Screens are crafted in a pipe-like structure using wires. These screens consist of two essential components: the outer V-shaped wire and the inner longitudinal rods.

The assembly process involves spirally wrapping the V Wire screen filter around a cage composed of longitudinal rods. The intersection of the shaped wire and rod is securely welded together using resistance welding techniques.

The "V Wire Screen Filter" represents a highly regarded modern technology in the realm of rainwater harvesting. It offers several advantages over conventional filtration systems, including the conservation of precious space, reduced construction costs, and shorter construction timelines for filtration tanks. Its scientifically engineered design makes cleaning remarkably easy, leading to substantial savings in maintenance costs.

This innovative technology not only enhances the efficiency of rainwater harvesting but also contributes to environmental sustainability. Its versatility and effectiveness make it an ideal choice for modern filtration needs.

Details | Other Filter Method | V Wire Screen Filter System |

|---|---|---|

Filter Slots | Slots are scattered | Special Design gives Continuous Slot Openings across the periphery and length of the screen. |

| Material | PP,plastic,or other | SS 304 304L 316 316Lor as per Customer Requirement |

Open Area | Less Open Area. | V wire Continous Slots give larger Open Area |

| Size | Custom as per Required Length | Custom as per Required Length |

Cleaning & Maintenace | As the uppermost layer becomes obstructed, the rate at which water percolates into the well will diminish rapidly. | Raw water enters the screen assembly horizontally, commencing from the bottom of the pit. Consequently, all impurities settle at the bottom initially. This unique process ensures that the pit remains open at the top, facilitating a prolonged and more efficient recharge compared to conventional systems. |

Filtration Accuracy | The filtration accuracy is average, and particularly fine filtration cannot be achieved. | Can perform gas and liquid filtration, and the filtration range can be customized |

Crafted from stainless steel and capable of withstanding acid treatment to remove incrustations and prevent gravel blockages, ensuring an extended bore well lifespan.

These slots create a jetting effect, effectively injecting recharge water into the aquifer.

Compared to conventional slotted pipes, this design maximizes recharge rates while minimizing frictional head loss, consequently reducing incrustation rates.

Efficiently filters out a maximum amount of suspended solids from raw water, thanks to non-clogging slots that maintain a sustained recharge rate.

Streamlines the installation process, saving money, time, and energy.

Please contact us if you are looking for the V wire screen tubes!

Please tell us the detailed size, application scenarios, industry requirements, and filtration effects of the V wire screens you need, so that we can more accurately recommend a more suitable screen tube for you.

Reach out to us via email at admin@yuanlvfilter.com or phone at 86-311-85955658 to tap into our expertise today!