Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

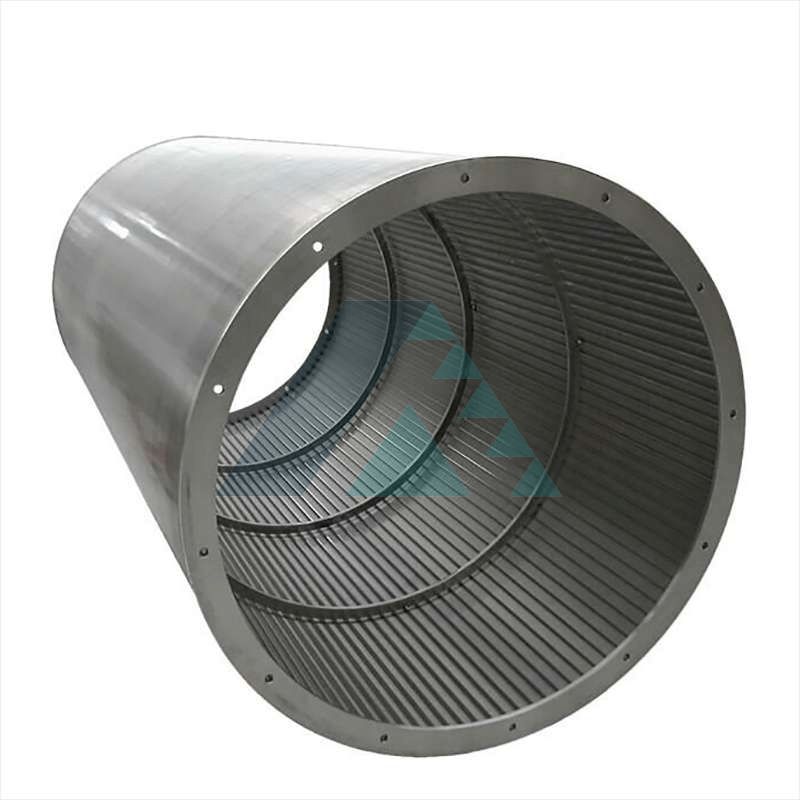

A trommel screen, also known as a rotary screen, is a mechanical screening machine used to separate materials, mainly in the mineral and solid-waste processing industries.

Product Details

A trommel screen, also called a rotary screen, is a highly efficient mechanical screening machine designed to separate materials. It is widely used in industries such as mineral processing, solid waste management, food processing, and more. Trommel screens are available in various configurations, including concentric screens, parallel arrangements, and series designs, to meet the specific needs of diverse applications.

Efficiently classify solid waste by size for improved recycling and disposal.

Enhance the recovery of fuel-derived waste materials.

Aid in wastewater treatment by separating solids from liquids.

Grade raw materials to recover valuable minerals.

Remove dust and fine particles during ore classification.

Used in mining operations for dewatering, sizing, and grading.

Separate compost into size fractions, removing contaminants and incompletely processed residues.

Sort dry foods like peas, nuts, and grains by size and shape.

Handle small yet durable food items efficiently under rotational force.

Rotary wedge wire screens remove impurities from pulp and recover fibers.

Separate solids from liquids to ensure product quality and enhance process efficiency.

Durability: Built to withstand mechanical stress, offering a longer lifespan.

Low Noise: Operates vibration-free, making it quieter than vibrating screens.

Cost-Effective: More affordable to produce compared to vibrating screens.

Versatility: Adaptable to a wide range of materials and applications.

Trommel screens are cheaper to produce than vibrating screens. They are vibration-free which causes less noise than vibrating screens. Trommel screens are more mechanically robust than vibrating screens allowing them to last longer under mechanical stress.

However, more material can be screened at once for a vibrating screen compared to a trommel screen. This is because only one part of the screen area of the trommel screen is utilized during the screening process whilst the entire screen is used for a vibrating screen.

Roller screens are preferred to trommel screens when the feed rate required is high. They also cause less noise than trommel screens and require less head room. Viscous and sticky materials are easier to be separated using a roller screen than with a trommel screen.

Curved screens are able to separate finer particles (200-3000 μm) than trommel screens.

The screening rate of a curved screen is also much higher than the trommel screen as the whole surface area of the screen is utilised.

With over 10 years of expertise in designing and manufacturing custom wedge wire and stainless steel products, we offer solutions tailored to your exact needs. Whether you require reliable screening for waste, minerals, or food, we deliver high-quality trommel screens that meet the highest industry standards.

Contact us today to discuss your requirements and get a free quote!