Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

Our advanced porous Sintered Metal Powder Filters offer exceptional performance across a wide range of demanding applications, ensuring efficient filtration for various products. These filters are manufactured by pressing metal powder into porous sheets or tubes, followed by high-temperature sintering. The resultant porosity allows them to be highly effective in liquid and gas filtration, gas/liquid flow control, and ventilation applications.

Compared to other filter materials such as glass fiber, stainless steel wire mesh, ceramics, and filter paper, sintered metal filters boast superior mechanical and compressive strength. They are particularly advantageous in applications involving continuous high temperatures and corrosive environments, significantly improving the filtration process and reducing operating costs. These filters are prevalent in chemical and petrochemical processes, oil refineries, pharmaceutical production, and semiconductor manufacturing. When compared to leaf filters, filter bags, and plate and frame filters, sintered metal powder filters prove to be more effective at particle removal, offer more reliable performance, are easier to clean, and have a longer service life.

Sintered metal media provide excellent filtration performance for separating particulate matter from liquid or gas process streams across numerous industrial applications. Fabricated from metal fibers or powders, these filtration elements are widely used in the chemical process, petrochemical, and power generation industries. Applications often require particulate removal to protect downstream equipment, facilitate product separation, or comply with environmental regulations.

We offer multiple product solutions for hot gas filtration in industrial applications, with operating temperatures often exceeding 750°C for extended periods. These filters typically operate in systems with automatic self-cleaning capabilities, and the filter elements must be capable of full regeneration on each cycle.

Our sintered metal filter elements are designed for applications requiring gas-liquid contact for reactions such as stripping, mixing, or diffusion. We help you maximize process efficiency by recommending and designing the most suitable solution from a wide variety of available sparger units.

With a weld-free design and "solid-solid" connection, our filter elements offer a longer lifespan than most competing solutions.

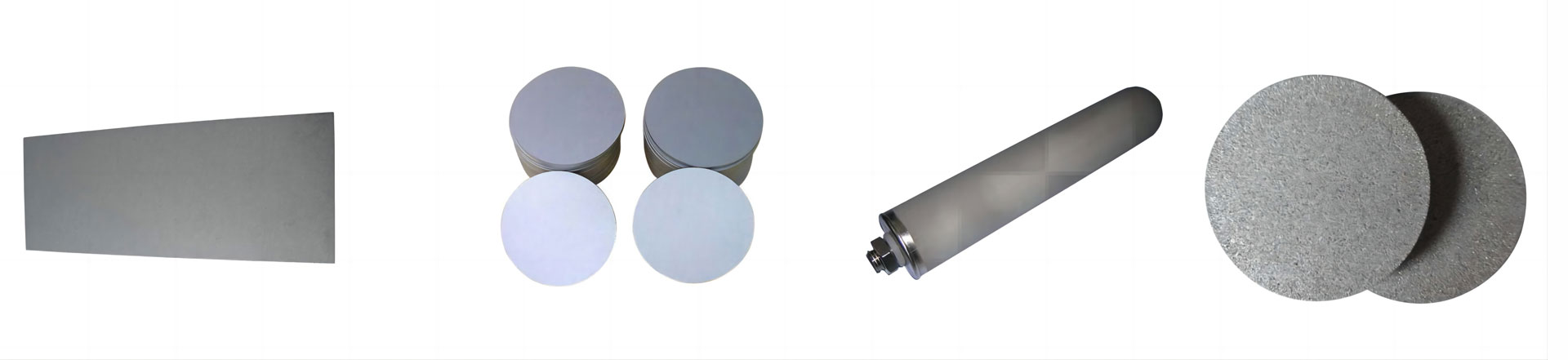

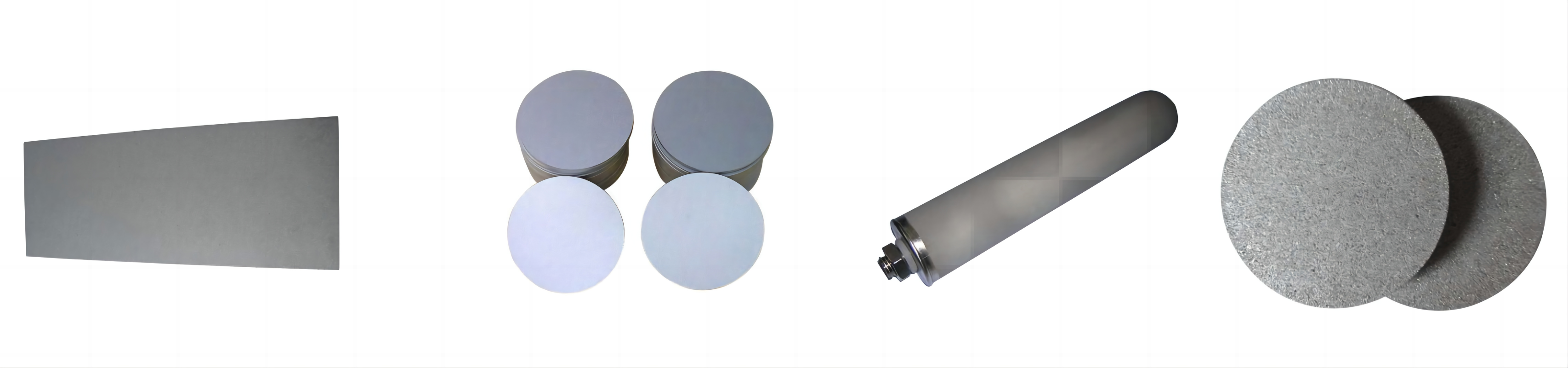

We design and manufacture various sintered metal filters to meet your specific needs, including sintered stainless steel filters, sintered bronze filters, sintered filter discs, sintered wire mesh, sintered metal powder filter cartridges, and sintered stainless steel sheet plates.

Sintered porous metal filter elements are primarily used in low-flow systems and can withstand temperatures up to 1000°C (1832°F) depending on process conditions. YUANLV can design customized sintered metal filter elements tailored to your specific filtration requirements.

We design and manufacture various sintered metal filters depending on your specific needs, such as sintered stainless steel filters (sintered porous stainless steel filters), sintered bronze filters, sintered filter disc, sintered wire mesh, sintered metal powder filter cartridge, sintered stainless steel sheet plate, etc.

Dimensions: Customized dimensions available.

Configurations: Tubular, slab-like, candle type, flake-like, discal, ring-like, rod-like, cone.

-Application (filtration, fluidization, gas dispersion in liquid, silencer, etc.)

-Gas/liquid flow

-Possible corrosion problems

-Process pressure and temperature of gas/liquid

-System pressure drop

-Expected gas preservation purity and particle retention

-Dimensions, shape, and tolerances

-Cleanliness requirements

-Mounting or support method

-Density and viscosity of the medium

YUANLV can design the optimum allocation suitable for your system configuration. We are honored to be your best sintered metal filter supplier.

Contact us today to discuss your specific filtration needs and discover how our advanced sintered metal filter solutions can enhance your processes.

Previous: Wedge Wire Application