Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

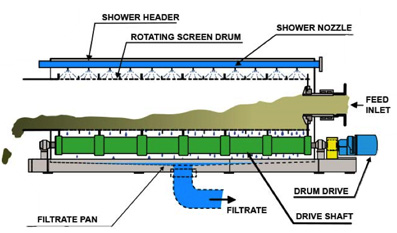

The Rotating Drum Thickener (RDT) is capable of increasing the solids content in wastewater slurries & reducing overall sludge volumes. Volume reduction of up to 90% is achievable in preparation for disposal or further dewatering processes.

The RDT can be integrated into wastewater treatment systems to improve the operating efficiencies of existing technologies. Some of the belt filter press is designed to mate with the RDT, creating a complete dewatering package.

Rendering

Tannery

Slaughterhouse

Poultry Processing

Food & Beverage

Pulp & Paper

Industrial Wastewater

Primary Sludge

Waste Activated Sludge

Industrial Slurry / Sludge

The Rotating Drum Sludge thickeners are optimal for medium to large capacity sludge thickening, enhancing process efficiency and achieving more cost-effective dewatering.

Externally Fed Rotary Drum Screens are automatic self-cleaning inclined screens based on the needs. The wedge section is fabricated from sheet or prefabricated grid.

Typical applications:

separation of various solids and sludges from municipal and industrial wastewater, food processes, pulp and paper production, and rendering processes;

removal of extruded pellets from cooling baths;

and separation of debris from any variety of plant and equipment-cleaning processes.

High efficiency

Different power engine options

Compact and stylish design

Suitable design for different capacities

Mining Industry

Fabricated parts entirely manufactured from 304 L / 316 L SS

More details, Please contacts Us

Previous: None