Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

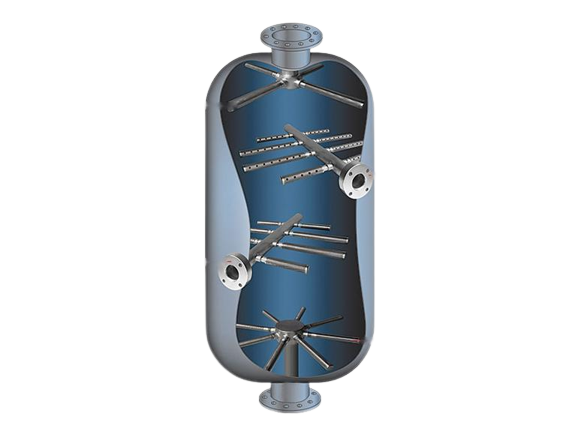

A lateral screen assembly water header system comprises an arrangement of screen laterals interconnected to a central header pipe or a hub. This system finds diverse applications, including ion exchange and sand filtration processes, effectively retaining media within various treatment setups.

The term "Versatile" succinctly encapsulates the essence of a Johnson screen lateral assembly system.

Tailored for efficient media retention across a wide array of applications, lateral assembly systems are linked to a central pipe or hub. These assemblies consist of an array of lateral screen tubes, ensuring uniform collection and/or distribution throughout the treatment media.

The lateral assembly with center pipe is highly adaptable, accommodating vessels of varying sizes and shapes. These systems support side, center, top, or bottom-inlet piping and can be engineered to manage flow in any direction.

In a standard water filter vessel, a header lateral assembly situated at the top evenly disperses inflow over the bed surface. A secondary assembly near the vessel bottom collects the treated flow and directs it either through the vessel sidewall or, by connecting the laterals to a central hub, out through the vessel bottom. For counter-current flow, a comparable distribution and collection system can be devised.

To address specific process chemistry or conditions, lateral screen assemblies can be fashioned from nearly any weldable metal, encompassing various grades of stainless steel and exotic alloys.

Key Points:

--Lateral screen assemblies are typically manufactured from Type 304 or 316 stainless steel, with the option of other weldable metals.

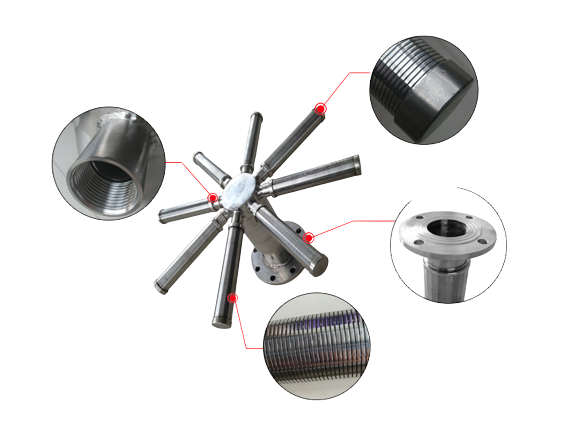

--Attachment of laterals to headers or hubs can be achieved through threaded fittings, couplings, or flanges.

--Lateral spacing, length, diameter, and slot opening dimensions are determined by individual system requirements.

--Perforated pipelines can be integrated within screen laterals to enhance collapse resistance and optimize flow distribution.

--Pre- and post-fabrication treatments, such as passivation, pickling stress relief, polishing, and plating, are available.

--Customized filtration solutions are also provided.

Rapid and gravity sand filters

Activated carbon vessels

Demineralizers/water softener filters

Ion exchange columns

Pharmaceutical resin treatments

Liquid purification columns

The sand filter tank assumes a round or egg-shaped configuration. Water is purified as it traverses through the sand contained within the filter. A multiport valve directs water flow through the filter or initiates backwashing. These valves can be either top or side-mounted, functioning identically. In the filter position, water cascades over the sand bed, and as it percolates through, the sand's sharp edges ensnare particles. Clean water exits through the bottom lateral assembly, with laterals resembling wagon wheel spokes featuring tiny apertures along the top edge. This design permits clean water reentry into the pool while retaining sand and debris within the filter.

Possible reasons include a cracked or broken lateral, the need for multiport valve servicing, or air passage leading to channeling, thereby allowing debris to bypass the filter. Inspecting and replacing damaged laterals on the manifold is necessary in such cases.

YUANLV is the China lateral assembly for sand filter manufacturers and exporters, we can provide high-quality water header and lateral assembly products and can design water treatment filtration solutions to your requirements. You can contact us at any time if you have any questions.