Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

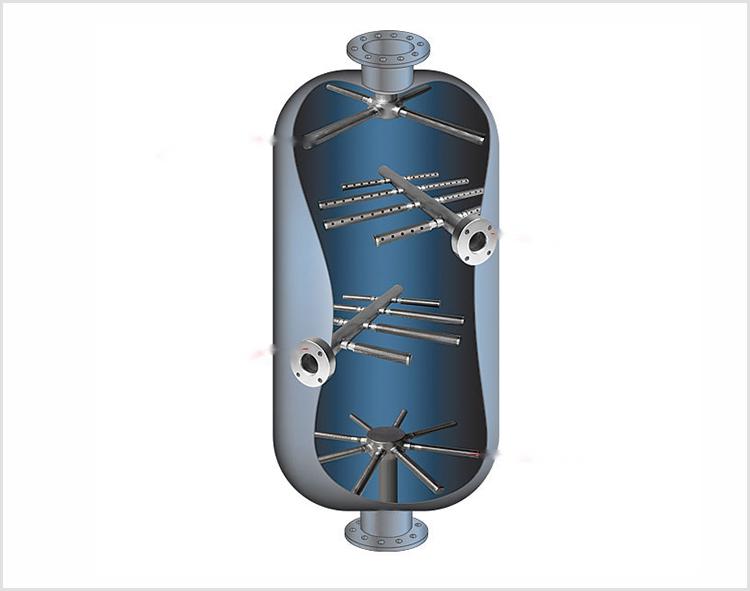

In the realm of water treatment, efficient media retention is crucial for achieving optimal results. Header Lateral Systems are engineered for optimal media retention across various applications. These systems, which connect to either a central header pipe or hub, consist of an array of screen laterals. This configuration ensures uniform collection and distribution of treatment media, enhancing the efficiency of various water treatment processes.

Header Lateral Screen Systems can easily accommodate various vessel sizes and shapes with versatile inlet piping options including side, center, top, or bottom inlet configurations. Designed to handle flow in any direction, these systems offer unparalleled flexibility.

For instance, a typical vessel might utilize a header lateral assembly at the top to distribute inflow uniformly across the media surface. A second assembly at the vessel’s bottom could collect the treated flow and channel it through the vessel sidewall or, by attaching the laterals to a central hub, out of the vessel bottom. A similar distribution and collection setup can be designed for counter-current flow applications.

Several design options are available to ensure uniform, controlled flow rates and collection efficiency. This adaptability makes Header Lateral Systems suitable for a variety of water treatment processes such as softening, ion exchange, demineralization, and many others.

These Header Lateral Screen Systems are used to:

Collect and distribute treating liquids

Retain treatment media

Distribute backwash flow

Filter solids

Our Header Lateral Systems are tailor-made to suit specific flow rates, pressure drops, media sizes, and vessel dimensions. The base pipe, header, fittings, and screens are crafted from high-grade stainless steel (SS 304, 316, 316L) as per customer requirements.

Our manufacturing process utilizes high-quality wedge wire screens to produce Hub and Lateral assemblies. Typical configurations include horizontal herringbone styles and vertically secured round hubs. With the capability to form wire onsite, we maintain strict control over all variables in the wedge wire screen manufacturing process. This allows us to offer a comprehensive range of wedge wire screen diameters and lengths.

These systems are designed for effective liquid or solid retention in a variety of applications including:

--Exchangers

--Clay and sand filtration

--Carbon towers

--Power plant water systems

Every Header and Hub-Lateral System we create is meticulously designed based on your specific requirements. Key design conditions include vessel inside diameter, volumetric flow rate, allowable pressure drop through the screen, media to be retained, and minimum open area. Therefore, it is crucial to collaborate closely with our team during the design and engineering stages to ensure all screen characteristics are fully accommodated.

By working together, we can ensure that your Header Lateral System meets all operational needs, delivering exceptional performance and reliability. Contact us today to discuss your project and discover how our custom-designed Header Lateral Systems can enhance your treatment process.

Previous: Wedge Wire Flat Panels for Mining

Next: Wedge Wire Application