Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

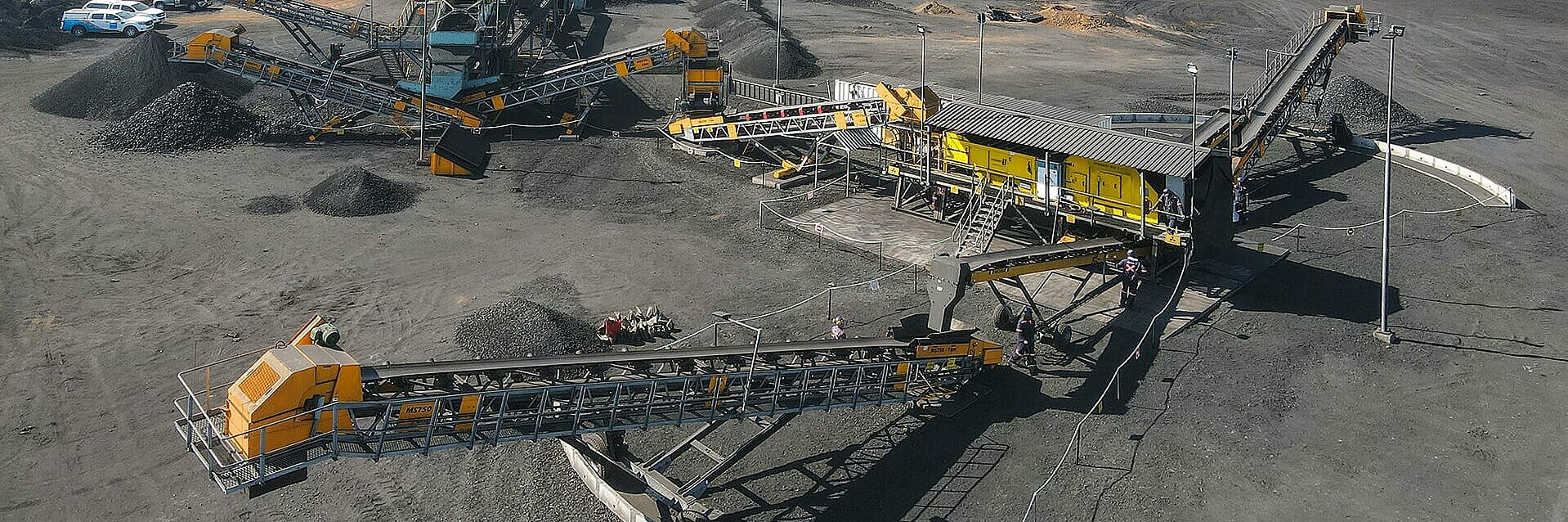

Coal processing or coal beneficiation uses physical (mechanical) and/or chemical methods to remove rocks, dirt, ash, sulfur and other contaminants and unwanted materials to produce high-quality coal for energy in local and export markets.

** Screening equipment

** Gravity separation equipment

** Beneficiation Equipment

** Dewatering equipment

When developing coal processing solutions, we consider ore characteristics, process requirements and environmental constraints to achieve your desired coal quality in terms of calorific value and the level of inherent mud and ash.

YUANLV helps you customize and optimize your coal beneficiation process to achieve the required product specification!

We offer all-inclusive services to coal yards for coal and coke screening. We provide professional advice, implementation support, design documentation, aftercare and replacement parts,especially the screen stainer equipment.

We advise on the selection of industrial screen types and parameters.

With the right screen type selection and parameters selection, we help optimise the efficiency and costs of screening, classification, dewatering and enrichment processes. We manufacture a wide variety of bespoke industrial screens, including slotted screens, Centrifuge screens and polyurethane screens. With the available installation systems, special hardware and dedicated accessories, you will install our screens on all types and models of vibrating screens and Centrifuge basket.

Initial classification

End classification

Washing Coal process

Wet screening

Dry screening

Recycling

Dewatering

Enrichment

Desilting

We offer polyurethane screens are made with self-relieving apertures resulting in the unrestricted downward movement of any sized particle – eliminating pegging and blinding from your coal screening.

We manufacture three varied dimensions of static and reversible sievebend housing units for coal screening. Both units are suited to polyurethane and wedge wire sievebends.

Static screens for coal screening are designed to reduce the initial load of material ahead of vibrating screens. The wetted surfaces can be polyurethane, rubber or ceramic.

Vibrating screen centrifuges for coal screening achieve long-lasting performance in the toughest coal dewatering applications. This is achieved with a polyurethane door and inspection cover, a steel feed pipe protected by ceramic wear linings and a durable segmented wedge wire screen fitted in a robust design cage.

drum screen has many advantages such as wide adaptability of coal type, simple coal feeding mode, high screening efficiency, large screen component, low energy consumption, low noise, strong sealing performance, long service life, small maintenance, and convenient maintenance.It overcomes the problem of screen clogging in the screening of wet materials by circular vibrating screens and linear screens and improves the screening system.

We manufacture centrifuge baskets based on our v wire slotted screens. Proven designs, sturdy reinforcements, precise manufacture and compliance with required tolerances make them ideal for most models of centrifuges.

Our coal screening equipment, rated among the highest quality, is used in coal preparation plants (MCPP) and modular coal preparation plants (MCPP) and are ideal for coal cleaning and sampling for a range of applications.