Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

In the realm of industrial filtration, innovation never rests. One such innovation that has taken the filtration industry by storm is the Wedge Wire filter. With its exceptional capabilities and unique design, this type of filter has become a game-changer for various applications.

In this blog post, we'll delve into the benefits of using Wedge Wire filters and how they can revolutionize your filtration processes.

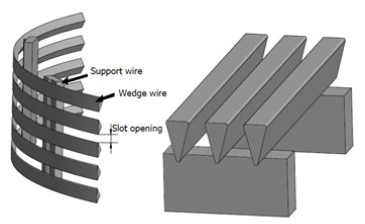

Wedge Wire is a unique screening and filtering material that can be used in many industries. It precisely welds the contour to the support contour at a set distance by accurately welding the V-shaped (or "wedge") contour. The gap between the wedge wires allows liquid to pass through, and anything too big will filter on the other side.

Wedge Wire is a unique screening and filtering material that can be used in many industries. It precisely welds the contour to the support contour at a set distance by accurately welding the V-shaped (or "wedge") contour. The gap between the wedge wires allows liquid to pass through, and anything too big will filter on the other side.

Wedge Wire filters are renowned for their precision filtration capabilities. The distinctive V-shaped wires create a wedge-like structure that allows for finer filtration compared to traditional filters. This design ensures that even the smallest particles are effectively captured, resulting in a cleaner end product.

Constructed from robust materials like stainless steel, Wedge Wire filters boast impressive strength and durability. This durability translates to a longer lifespan and reduced maintenance requirements. Whether you're dealing with abrasive materials or high-pressure applications, Wedge Wire filters can withstand the rigors of demanding environments.

Efficient flow rates are crucial in industrial processes, and Wedge Wire filters excel in this aspect. The design of these filters minimizes clogging and pressure drop, allowing for a consistent and smooth flow of liquids or gases. This enhanced flow rate not only improves productivity but also contributes to energy savings.

The unique design of Wedge Wire filters provides a significantly larger filtration area compared to traditional filters. This expanded surface area allows for higher dirt-holding capacity and longer operational cycles before maintenance is required. As a result, downtime is reduced, and productivity is maximized.

No two filtration needs are exactly the same, and Wedge Wire filters offer a range of customization options to cater to diverse requirements. From varying slot sizes to different wire profiles, these filters can be tailored to suit specific applications, ensuring optimal filtration efficiency.

Maintaining Wedge Wire filters is a breeze. Their design minimizes the accumulation of debris, and when cleaning is necessary, the filters can be easily backwashed or cleaned in place. This simplicity in maintenance translates to less downtime and increased overall efficiency.

Wedge Wire filters find applications across a wide spectrum of industries, including water treatment, food and beverage, pharmaceuticals, petrochemicals, and more. Their adaptability and effectiveness make them a versatile choice for diverse filtration needs.

The screen of the vibrating screening machine

Water/Wastewater treatment

Rotating drum screen

Construction industry

Reactor floor

Reactor element

Insertion of pressure filter

Coal Mine industry

Chemical industry

Incorporating Wedge Wire filters into your filtration processes can lead to a plethora of benefits, from unparalleled precision and durability to increased flow rates and enhanced filtration area. As an innovative solution, these filters are setting new standards in the world of industrial filtration. Embracing Wedge Wire technology can not only improve the quality of your end products but also streamline your operations, reduce maintenance costs, and contribute to a more sustainable future.

Next: Wedge Wire Screen