Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

"Versatile" is the best single-word description of a Johnson screen lateral assembly system.

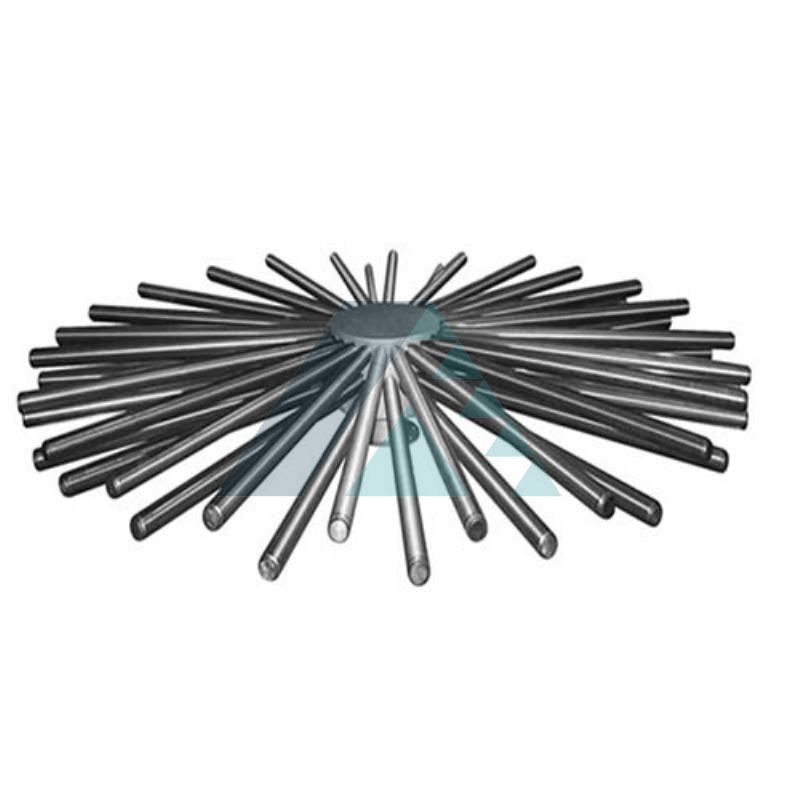

Lateral screen assembly water header Distributor systems consist of a series of screen laterals connected to either a central header pipe or a hub. They are used for effective media retention in lots of applications, including ion exchangers, and sand filtration applications.

Product Details

Lateral assembly systems are designed for effective media retention in a wide range of applications. Connected to either a central header pipe or hub, these assemblies consist of a series of lateral screen tubes that allow a uniform collection and/or distribution through treatment media.

"Versatile" is the best single-word description of a Johnson screen lateral assembly system。

Lateral assembly with center pipe easily accommodates a wide variety of vessel sizes and shapes with side, center, top, or bottom-inlet piping, and can be designed to handle flow in any direction.

Wedge wire lateral assemblies are made of several wedge wire screen laterals and supporting round hubs. There are thread ending and flange ending wedge wire screen laterals for choice to suit different machines.

Lateral Assembly Systems Application:Lateral assembly readily adaptable technology for a number of water treatment processes such as Softening and ion exchange, Demineralization, and many others. These are used to collect & distribute treating liquids, retain treatment media, distribute the backwash flow, or filter solids. as: Under draining filtration Ion exchanger Cation exchanger Mixed bed exchanger

| Lateral Assembly Systems Benefits and Advantages:--Continuous & uniform slot design, Enhances Efficiency. --Economical due to Corrosion and rust resistance long life, and easy to install and replacement. --Ability to withstand high load & pressure --Customizing design --Efficient Backwash --Reduces maintenance and shutdown costs

|

The Hub Radial Lateral Assembly, which can be affixed to the upper or lower section of vessels, offers an economical solution for water filter vessels. This lateral assembly system can be tailored precisely to your application requirements, functioning as both a down-flow service collector and an incoming backwash water distributor. Moreover, in scenarios involving counter-current flow—wherein the inlet occurs at the vessel's base—the arrangement is reversed. Here, the distributor resides at the vessel's bottom while the collector occupies the upper portion.

The wedge wire screen utilized can be designed as a perforated pipe for high-pressure vessels or engineered to ensure uniform flow distribution across the entire screen surface.