Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

Wedge Wire Header Lateral Distributor Screens Provide Tank Filtration Solutions that can ensures uniform distribution and collection, serving as a critical component in various fluid treatment processes.

Product Details

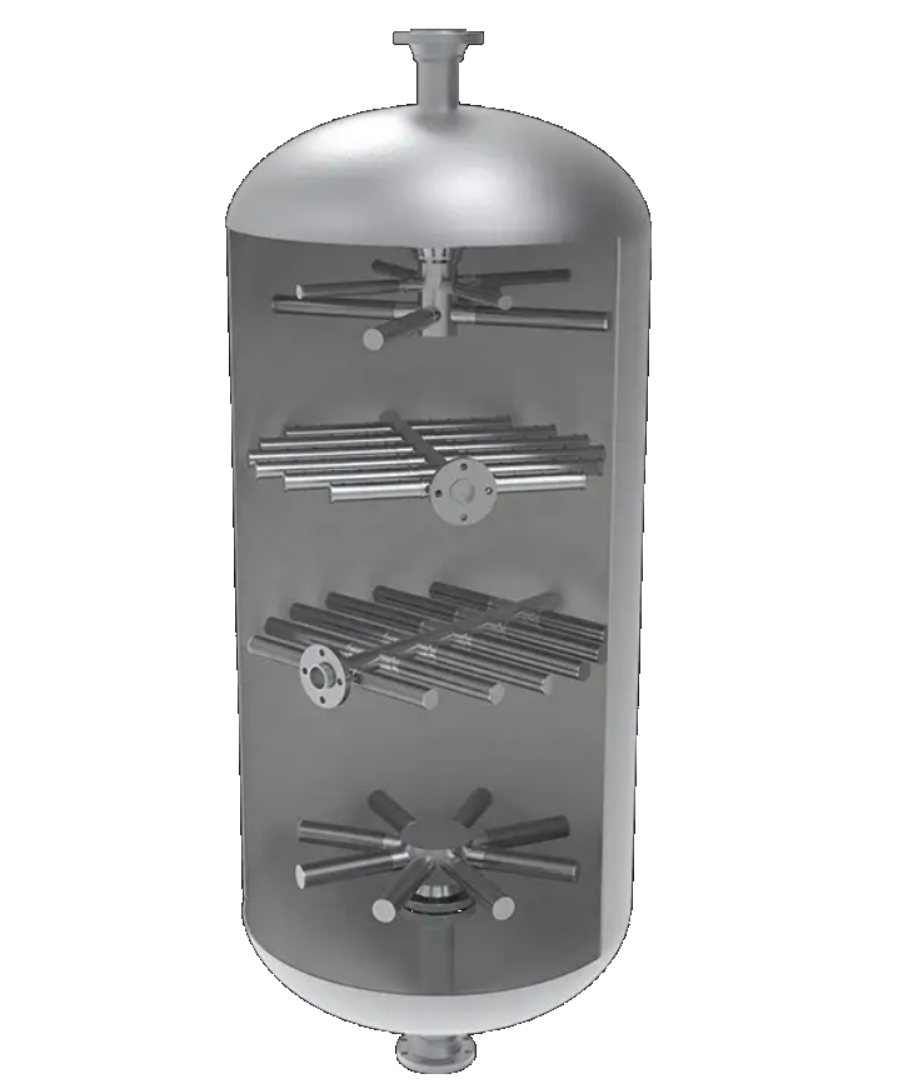

Wedge Wire Header Lateral Distributor Screens Provide Tank Filtration Solutions that can ensure uniform distribution and collection, serving as a critical component in various fluid treatment processes.

Header lateral systems comprise a series of screen laterals connected to a central header or hub. These assemblies empower process engineers to design for consistent flow through treatment media across a wide range of rates vessel sizes and shapes.

In a typical setup, a header lateral assembly is positioned at the top of the vessel to evenly distribute inlet flow across the bed surface. Another assembly, located at the bottom of the vessel, collects the treated flow, ensuring uniform fluid distribution throughout the vessel's length and cross-section.

Header lateral design is most effective for vertical vessels and can be mounted either on the side or centrally. For horizontal vessels or square/rectangular underdrains, header lateral design is also utilized. Hub lateral design offers an economical option for smaller vertical vessels.

Wedge wire lateral assembly finds application in various filtration and screening tasks across different industries:

**-Rapid and gravity sand filters

**-Activated carbon vessels

**-Demineralizers/water softener filters

**-Ion exchange columns

**-Pharmaceutical resin treatments

**-Liquid purification columns

Choose wedge wire lateral assemblies for durable and reliable support in your mechanical devices, ensuring efficient fluid treatment and filtration processes.

Material | SS304, SS304L, SS316, SS316L, SS321, 904, C276, 2205, 2207, Duplex, Hastelloy, etc | ||

Normal Lateral Tube QTY (PCS) | 4, 6, 8, 12,16, etc. According to request, actual flow rating, and application. | ||

Lateral OD Range (mm) | 25 to 80mm, customized | ||

Normal Hub (mm) | 108, 133, 219, Customized | ||

Hub and lateral connector types | Thread, Flange | ||

Diameter Range(mm) | According to the tank diameter. (Usually 200mm shorter than tank diameter) | ||

Slot Range(mm) | Normal slot 0.2, 0.25, 0.3, 0.35, 0.4mm.Slot according to request. | ||

Wedge Wire(mm) | 1x2 | 1.5x2 | 2x3 |

Support Rod (mm) | 1.5x2.52x3 | 1.8x2.52x3 | 2x32x4 |

Note | Customized According To Requirement | ||

--High-Temperature Resistance: Exceptional stability even under high temperatures, withstanding extreme conditions above 100°C safely.

--Ample Flow Area: Enhanced fluid handling efficiency due to a wider flow area.

--Robust Construction: Reliable and stable performance over prolonged usage periods.

--Customized Filtration Accuracy: Tailored to specific needs, ensuring high-precision filtration for diverse applications.

--Low Pressure Loss: Minimal pressure loss during fluid transfer, maintaining system efficiency.

--Long Lifespan/Low Maintenance Cost: Ensures prolonged lifespan with minimal maintenance requirements.