Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

Header Lateral Screen: Optimizing Flow Distribution

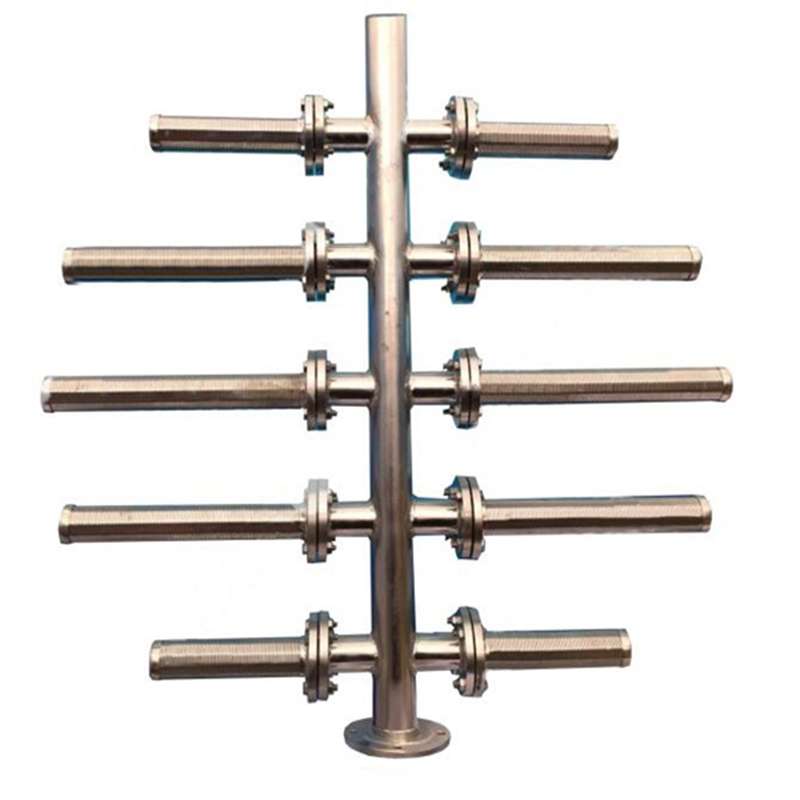

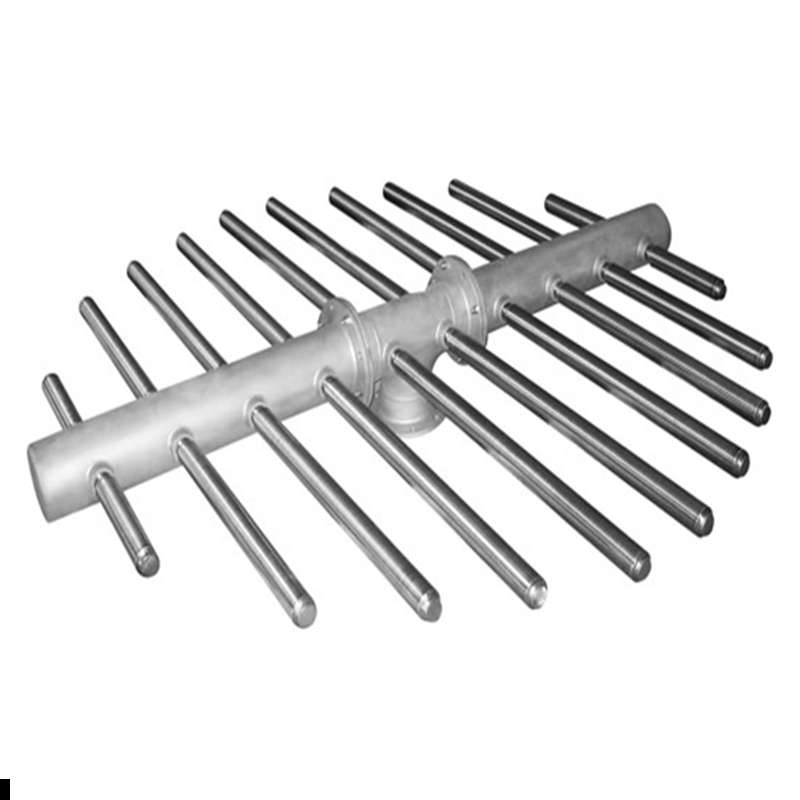

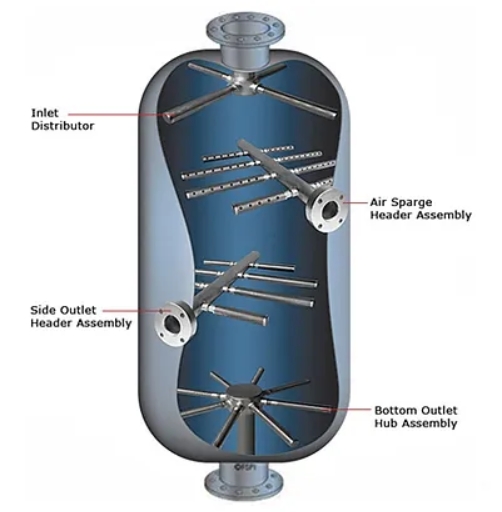

The Wedge wire Header Lateral screen system is meticulously engineered to ensure efficient media retention across various applications. These assemblies, connected to a central header pipe or hub, consist of screen laterals designed to uniformly collect and distribute process flow through treatment media.

Product Details

The Wedge wire Header Lateral screen system is meticulously engineered to ensure efficient media retention across various applications. These assemblies, connected to a central header pipe or hub, consist of screen laterals designed to uniformly collect and distribute process flow through treatment media.

--Versatile Application: Designed to accommodate a wide range of vessel sizes and shapes with various inlet piping configurations, allowing for flexibility in installation.

--Optimized Flow Handling: The system can handle flow in any direction, ensuring efficient distribution and collection of process water in applications such as ion exchange and organic matter removal.

--Efficiency and Pressure Drop: Sizing of the main header pipe and screen laterals is based on recommended velocities to optimize efficiency and minimize pressure drop, crucial for preventing resin or media migration.

--Custom Design: Each system is carefully engineered based on specific design conditions provided by the client, ensuring compatibility with vessel dimensions, flow rates, pressure drop limits, and media retention requirements.

Removable Screen Laterals: Screen laterals can be easily removed for maintenance or replacement, facilitating hassle-free operation and minimizing downtime.

Durable Construction: Constructed with high-quality materials, the Header Lateral Screen offers exceptional mechanical strength, temperature resistance, pressure resistance, aging resistance, and corrosion resistance, ensuring long-term reliability in demanding industrial environments.

Water treatment processes such as ion exchange and organic matter removal

Industrial filtration and separation applications

Chemical processing and refining industries

Petrochemical and oil refining facilities

**-Uniform Water Distribution: Ensures even distribution of water across the bed surface, optimizing treatment efficiency.

**-High Mechanical Strength: Provides robust support and durability in harsh operating conditions.

**-Temperature Resistance: Suitable for handling fluids at elevated temperatures without compromising performance.

**-Pressure Resistance: Withstands high-pressure environments, maintaining structural integrity.

**-Aging and Corrosion Resistance: Resistant to degradation from prolonged exposure to harsh chemicals or environmental conditions.

The Wedge wire Header Lateral screen system offers unparalleled performance and reliability in optimizing flow distribution and media retention across various industrial applications. With its custom-engineered design, durable construction, and versatile application, it stands as a cornerstone for efficient water treatment and filtration processes.

Experience the advantages of uniform flow distribution and superior durability with our Header Lateral Screen – engineered for excellence, built for reliability.