Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

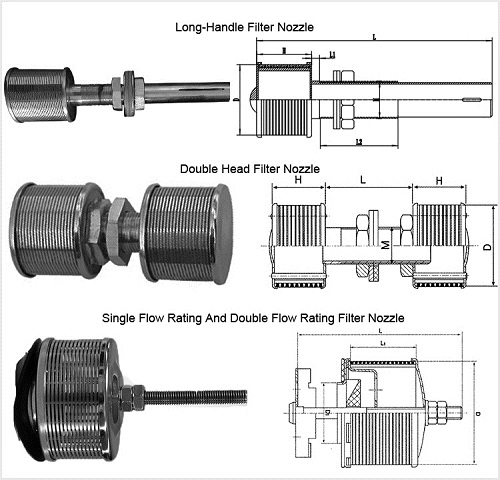

Wedge wire screen water filter nozzles are custom-engineered in wedge wire screen to meet specific customer flow rate requirements. Our water filter nozzles can be integrated into filtration or treatment systems to optimize the effectiveness of the treatment media.

Product Details

Wedge wire screen water filter nozzles are custom-engineered in wedge wire screen to meet specific customer flow rate requirements. Our water filter nozzles can be integrated into filtration or treatment systems to optimize the effectiveness of the treatment media.

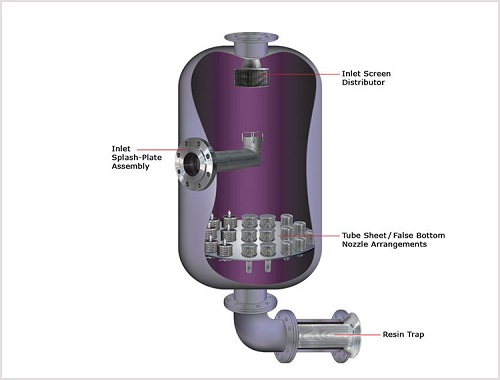

Because of their non-clogging design strainer are effective in a wide range of water treatment and other industrial applications. Common applications include under drain media retention elements or flow distributors in deminer analyzers and water softeners in pressure and gravity sand filters. Strainers can also be used as collectors at the bottom of the vessels by installing a number of strainers uniformly across a tray plate.

The combination of a high open area and a non-plugging slot design makes this nozzle /collector application pupilar.

Our factory can design manufacture different types of wedge wire screen water nozzles.

Advantages of the wedge wire screens filter nozzle

1. Excellent roundness

2. Very good slot width precision

3. High mechanical load capacity

4. No form closure connection that would allow vibration of the profiled bars V-shaped wire around the twin tube water cap for metallurgical industry

5. Automated welding process for high-precision manufacturing

6. Perfectly adjusted screen basket profiles

7. Available for all screens

8. Surface finishing as required

Application of the wedge wire screens filter nozzle

The wedge wire screens water filter nozzle can be fixed on the filtering equipment for the filtration of water petrol resin and another medium. It can be widely used in water treatment, water softening, conversion of seawater into freshwater, the filter of food chemistry. Also, it can replace the Polypropylene ( PP ) filter, sand filters, carbon filters, ion exchange systems, carbon absorbers, media retention, backwash retention, resin retention, and resin traps.