Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

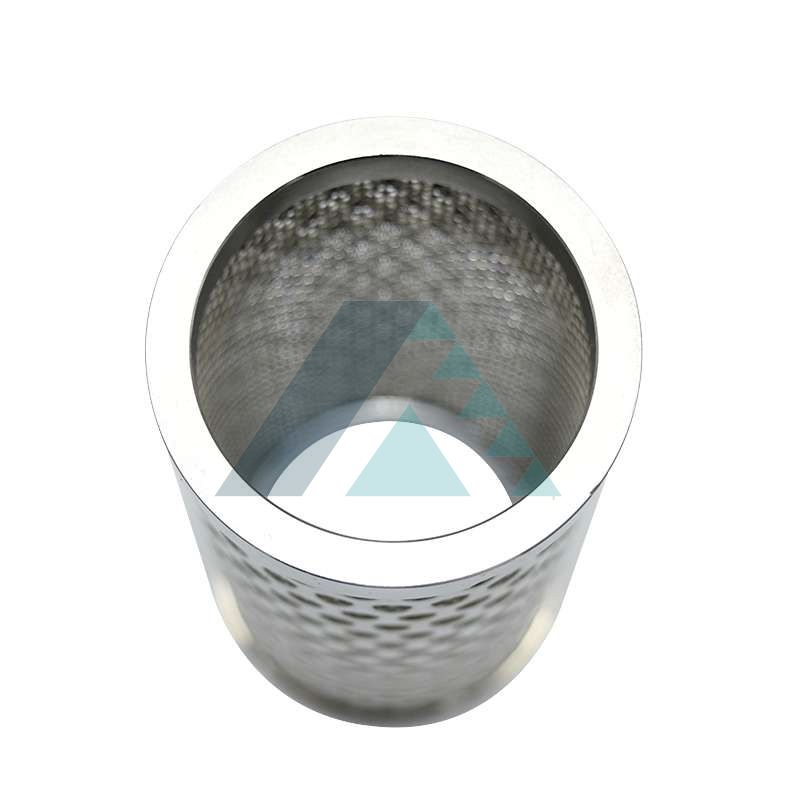

Perforated metal cylinder filters are mainly made of cut-to-size perforated stainless steel, perforated mild steel sheet, or punched aluminum by rolling up to a cylinder and welding together.

The perf steel filter tube can be manufactured individually or welded together with a single layer or multi-layers of woven wire mesh to reach a certain filtration precision.

Product Details

Perforated metal cylinder filters are mainly made of cut-to-size perforated stainless steel, perforated mild steel sheet, or punched aluminum by rolling up to a cylinder and welding together.

We can provide a wide variety of expanded metal mesh tube, welded mesh pipes and perforated cylinders and tubes suitable for use across a number of industry sectors.

The filter cylinder tube can be used in the manufacture of filters, exhausts, pipe guards, heat exchangers, vents, screening and decorative features, and in a wealth of other applications.

We manufacture welded expanded metal mesh cylinders and tubes for a range of applications.

Expanded metal mesh can be used to create bullet filters, capped filters, open-end flange filters and crimped-ended filters.

The expanded metal mesh is made of high-quality carbon steel plate stretched by a steel mesh punching and shearing machine, and the surface treatment adopts a galvanizing process. It is an important component of filters for inner supporting and outer protection.

We manufacture spiral tubes in a variety of widths and lengths, in materials including stainless steel, tin-plated steel, aluminum alloys, carbon steels, copper-based alloys and pre-coated steel. The tubes are manufactured without the need for welding and our equipment produces consistently high collapse strength tubes.

Our spiral tubes have applications in industries such as filtration, textiles, automotive and interior design.

We offer a range of perforated metal filters to the market, which can be designed to a bespoke shape if you require.

The perf steel filter tube can be manufactured individually or welded together with a single layer or multi-layers of woven wire mesh to reach a certain filtration precision. The woven wire mesh or wire cloth can be either welded inside or outside of the perforated tubes based on different filtration directions.

Our expanded metal mesh filter tubes are widely used in applications, not only in filtration but also in the chemical industry, automotive and new energy areas, etc. Here we list the most common applications below:

þ Air filter / liquid filter

þ Filter housing/covering of filters

þ Electro-chemical conductor in new batteries

þ Audio speaker or record player

þ Expanded metal shielding and radiant panel

þ Flame breaker

þ Internaseparators for toasters